The SUPERSCAN PM3D® is based on new scanning concepts invented in 2014 by METIS and aimed to respond to the special needs of the industrial, decoration and fine-art markets. Indeed, the SUPERSCAN PM3D® integrates innovative and patent protected technologies that allow to scan color and calculate 3D surface embossing information from it and at very high resolution even on large originals as: a long plank of natural wood, a bolt of fabric, a massive canvas, etc.

This scanner extends the lighting and scanning capabilities of the METIS DRS-DCS family providing the ability to illuminate originals from 8 independent light sources. Thousands of different light schematics are possible and achieved automatically through sophisticated software and hardware controls.

3D data for the generation of Depth, Normal, and Glossiness MAPs is based on illuminating the object from different directions and then applying unique proprietary METIS algorithms. These calculations result in a highly detailed 3D reconstruction of the original surface. A wide variety of textured or embossed surfaces can be scanned with optimal results, from wood to tile, wallpapers to painted canvases, even glossy materials such as glazed ceramic or metallic finishes.

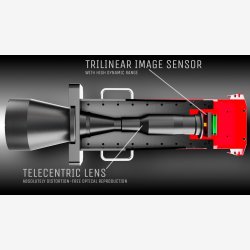

The SUPERSCAN PM3D® is the first scanner for the Decor industry that overcomes the resolution limits typical of image sensors thanks to an innovative opto-mechanical design which, among other things, allows a native optical resolution of 1200 PPI. Thanks to its X-Y-Z microscanning technology and special telecentric lens, the PM3D is capable of capturing, without any kind of distortion, originals up to 200 x 130 cm (78,74 x 51,2 in).

In addition, the METIS Scan Merge tool allows to scan very large originals (even those that exceed the scanning area) with perfect results.

The SUPERSCAN PM3D® adopts the new METIS Scan Director software that has been specifically designed to fulfill the requirements of the industrial, fine-arts and decorative markets and for handling 3D data.